It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

3. Adhesive products: various electronic, electrical appliances, special pads for mobile phones, silicone stickers, Velcro, conductive adhesive, strong double-sided adhesive.

4. Dustproof materials: cosmetic cotton, camera cotton, high-density sponge, filter cotton, dustproof net, non-woven fabric.

Main technical parameters

Model number

GW-MQ-320

Max. die cutting speed

300 times/min

Die cutting area

300*300mm(max-width='100%' width*length)

Diameter

600mm

Jumbo roll max-width='100%' width

300mm

Width Precision

0.5mm

Length precision

0.1mm

Total Power

4.5kw

Voltage

3 p 380v 50hz

Weight

2200kg

Overall Dimensions(LxWxH)

2.6x0.95x1.4 m

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

1. Mother reel end photocell with automatic stop. 2. Full rotary flexo printing module support sport varnishing/cold foil 3. Die cut unit able to work full rotary mode and semi rotary mode. 4. Precision cutting to reduce waste 3. Die cut station with servo register control. 4. Internet fault diagnostics . 5. Dual 3”pneumatic rewinder for a max roll diameter of 450mm with independent tension control.(optional )

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.

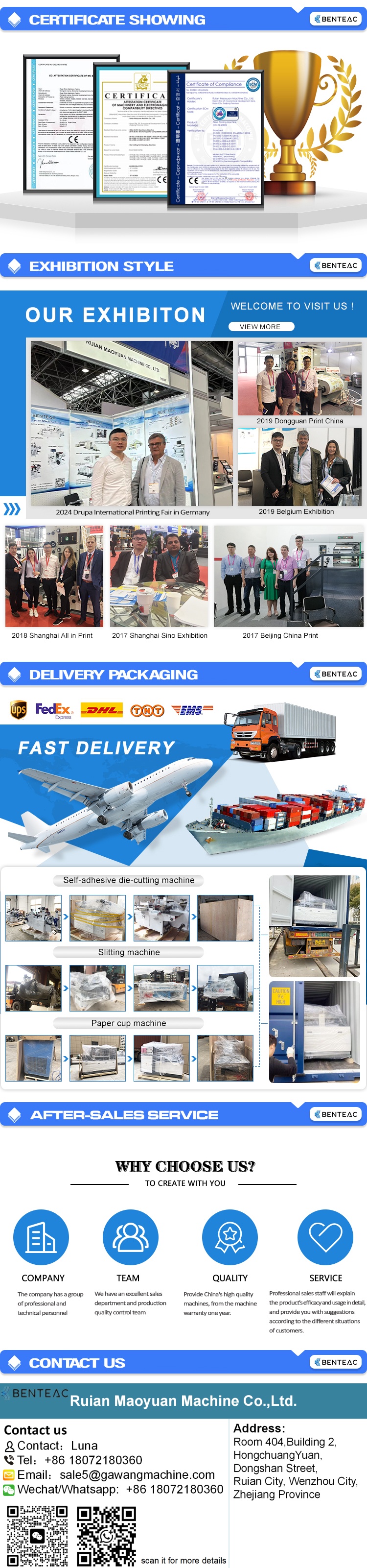

Welcome to our website! Please feel free to send us your questions by asking us, we will contact you and provide you with the services as soon as possible.